Services - Mechanical Design

The broadest engineering discipline

Mechanical engineering is a branch of engineering concerned with designing, producing, installation and operation of engines and machinery - ranging from relatively simple items to more complex machinery and even entire facilities and plants. Virtually anything that moves, whether animate or inanimate, falls within the scope of mechanical engineering from components to machines to the human body.

Mechanical engineering is particularly concerned with forces and motion and is the study of objects and systems in motion. It is concerned with the application of the fundamental principles and laws of nature to the development of products and machinery that accomplish convenience, automate tasks with the objective of improving quality and productivity.

Mechanical engineering plays a crucial role in shaping the technology and infrastructure that drive our modern world.

Mechanical engineering requires an understanding of core areas including mechanics, dynamics, thermodynamics, materials science, design, structural analysis, and electricity. In addition to these core principles, mechanical engineers use tools such as computer-aided design (CAD), computer-aided manufacturing (CAM), computer-aided engineering (CAE), and product lifecycle management to design and analyze manufacturing plants, industrial equipment and machinery, transport systems, motor vehicles, aircraft, watercraft, robotics, medical devices, weapons, and others.

It is in this requirement of complex fusion of technology and integration that our design & manufacturing consulting service founded on multi-domain collaboration help product companies get to the leading edge technologies and resources with the right experience and expertise so that they are able to innovate their ideas into realities and bring out state-of-the art mechanical products quicker while controlling costs, time, and quality.

We offer the full spectrum of mechanical engineering services with prototyping and manufacturing. Our services portfolio includes right from ideation to design to production.

Service Portfolio

Details

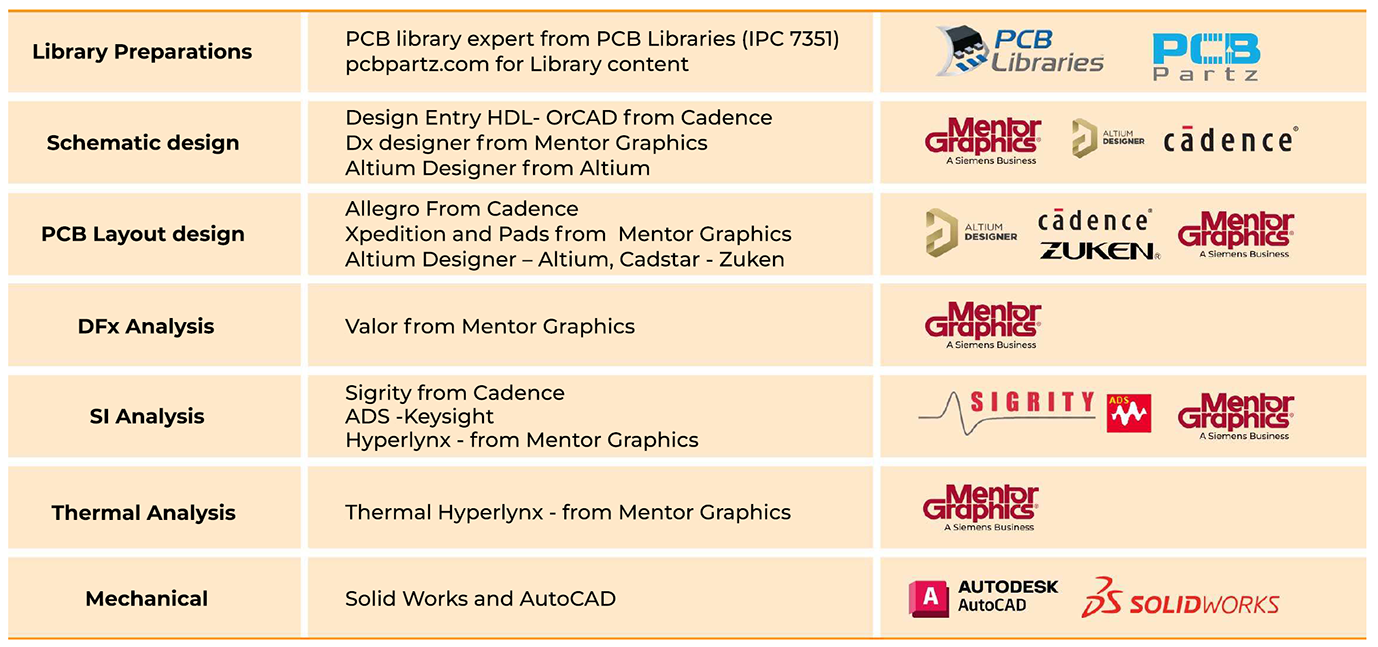

PCB Engineering Infrastructure

As adjustable as it can get to be ..

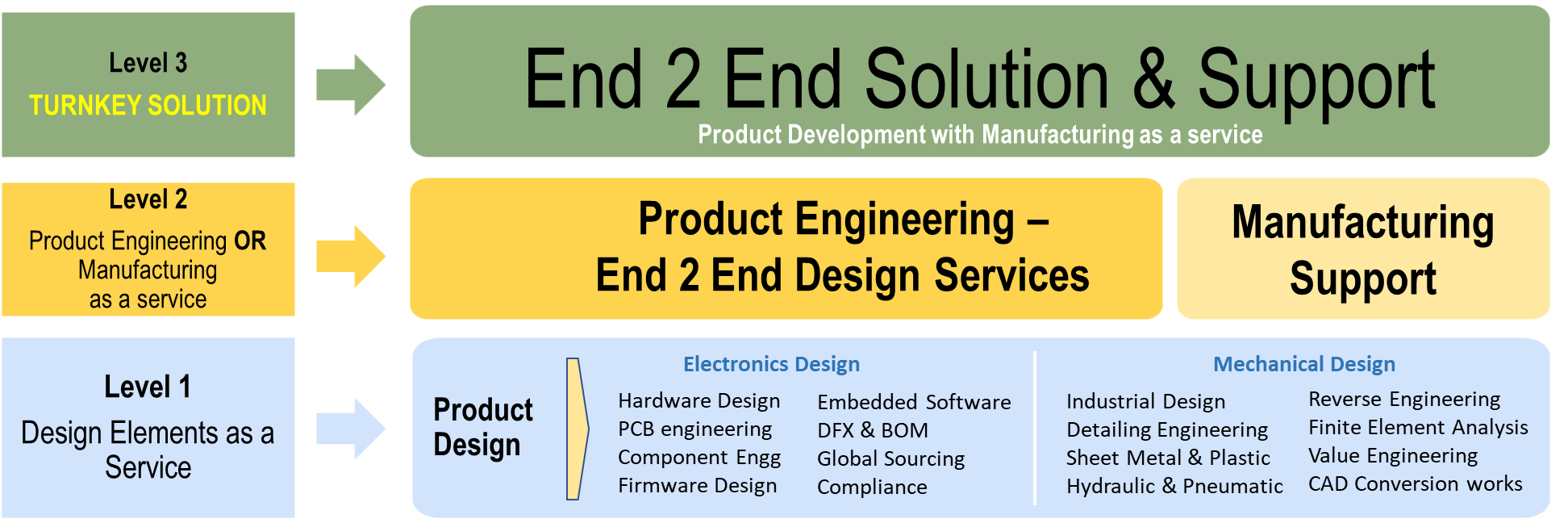

Modular Services - 3 Levels

Avantage offers the flexibility of 3 levels of service to choose from depending on the type of support required. This helps customer to engage with us at any design phase in their product development life cycle. This modular approach enables customer to pay for only what they need.

Level 1

Design Elements as a Service

Customers can consult for any specific design requirement in their product development cycle Eg. Hardware Design or Cad Conversion works

Level 2

Product Engineering OR Manufacturing

Customer can consult for either end to end product engineering services OR for their manufacturing requirements

Level 3

TURNKEY SOLUTION

Product Engineering + Manufacturing

Customers can consult turn key - to get their products designed and manufactured by us

As flexible as it can get to be ..

Engagement Models

Choose the engagement model that best suits your design and development requirement based on the type and volume of the work. These engagement models facilitates the flexibility of working with us for your requirements that range from few hours to turn key !

Fixed Price

Time and Material

This engagement is for the type of projects in which it is not possible to accurately estimate the size of the work, or when it is expected that the project requirements are most likely to change.

In this model client agrees to pay based upon the time spent by Avantage or one of it's partner to perform the work and for the materials used in the delivery of the project.

Dedicated Resources

Dedicated Resource is for clients who desire to get their engineering designs tasks that are mundane and have volume and require experienced resources to fulfil the tasks.

Dedicated professionals can be hired out from Avantage or one of it's partners.

These resources are full time employees at Avantage or one of it's partners working for the client from the Avantage partner engineering center in Bangalore, India.

Xtended Engineering

An engineering center at an off-shore destination as an extension of the local design center would be the best for such clients who desire to leverage the advantages of outsourcing to the maximum.

Avantage through it's partners can help establish offshore engineering center as an extension of the local design team at an off-shore destination and take care of all operational aspects to make the program a success for the client.

Customer is our partner

Our Quality Policy

We are committed to consistently providing high-quality solutions to our customers’, on time, to their expectation and to the best of their satisfaction. Our partners are with ISO 9001-2015 quality management system and are certified to develop medical devices, design for aerospace and automotive.